Precision Machining

At VEPC, we take pride in our commitment to precision machining, a cornerstone of our manufacturing prowess. With cutting-edge technology, skilled artisan, and a dedication to excellence, we have established ourselves as leaders in delivering high-quality precision-machined components across various industries.

Leveraging state-of-the-art CNC technology and skilled operator, Velocity Engineering and Project Consultants commit to quality extends across diverse industries, offering custom solutions that surpass expectations. With a focus on sustainability and customer satisfaction, VEPC are leaders delivering precision machined excellence.

MACHINES WE HAVE

| Sr.No | DESCRIPTION | MAKE | CAPACITY | QUANTITY |

|---|---|---|---|---|

| 1 | CNC Turning Center | MEUSER, GERMANY | X Axis (Diameter): 400mm Z Axis (Length): 4800mm | 1 Nos. |

| 2 | CNC Turning Center | HMT SBCNC 40 | X Axis (Diameter): 400mm Z Axis (Length): 3000mm | 1 Nos. |

| 3 | Horizontal Boring Machine | JUARISTI, SPAIN | Spindle Size: 205 mm Cross Axis X: 3000 mm Vertical Axis Y: 2500 mm Longitudinal Axis Z: 2500 mm Table Size: 2000 x 1750mm Table Load Capacity: 10Ton | 1 Nos. |

| 4 | Heavy Duty Lathes | Multiple | Max Job Length: 5800 mm Max Job Diameter: 600 mm | 17 Nos. |

| 5 | Heavy Duty Facing Lathe | Multiple | Max Job Length: 3000 mm Max Job Diameter 1200mm (Max Diameter: 2000mm) | 2 Nos. |

| 6 | Automatic Band Saw | SPM | Max Cut Diameter: 300 mm | 1 Nos. |

INDUSTRIAL REPAIR SERVICES

At Velocity Engineering and Project Consultants, we understand that the backbone of successful engineering and project consultancy lies in the seamless operation of industrial machinery. To ensure the uninterrupted flow of your operations, we proudly offer comprehensive industrial repair services tailored to meet the unique needs of your company.

Our Expertise: With a team of highly skilled technicians and engineers, we specialize in the repair and maintenance of a wide range of industrial equipment. From complex machinery to intricate electrical systems, our experts bring a wealth of technical knowledge and hands on experience to address the challenges specific to your industry.

Key Services: Prompt repair, Preventive Maintenance and Technical Precision.

Shaft Manufacturing

Shaft Manufacturing

At VEPC, we take pride in our commitment to delivering high-quality shafts that meet and exceed the stringent demands of diverse industries. Our shaft manufacturing process is a testament to precision engineering, advanced technology, and unwavering dedication to quality.

Our manufacturing process involves, Material expertise, Cutting-edge machining, Advanced heat treatment, Surface finishing excellence, Rigorous quality control, Customization for unique needs and environmental responsibility.

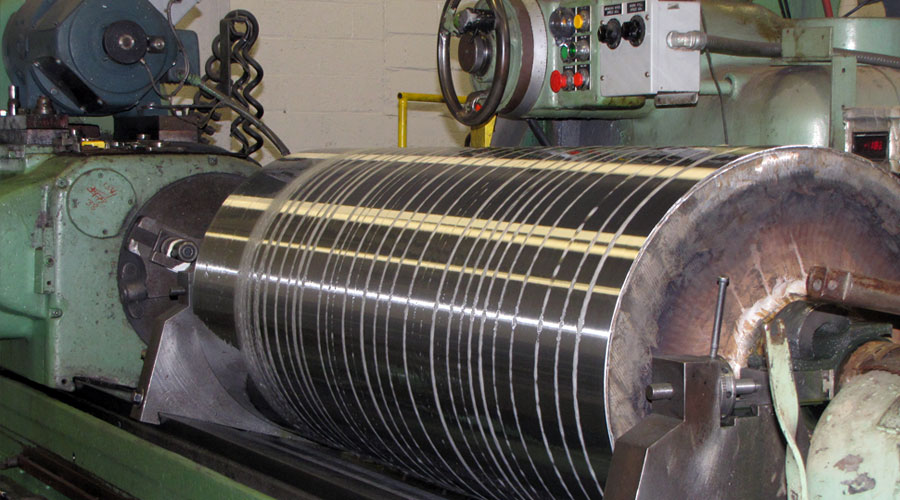

Precision Roll Grinding

Precision Roll Grinding

VEPC is where precision meets perfection in roll grinding solutions. We redefine precision in roll grinding, with our dedicated focus on quality and accuracy, our unmatched expertise, and with our state-of-the-art technology. We are the trusted choice for industries where every micron matters.

precision grinding

precision grinding

Precision grinding is a cornerstone of manufacturing industries, ensuring that critical components meet exact specifications for optimal performance. At Velocity Engineering and Project Consultants, we take pride in our commitment to precision grinding, a practice that goes beyond routine tasks and transforms into an art form, setting us apart in the competitive landscape of industrial services.

Precision grinding is an art mastered by our skilled technicians at VEPC. With a blend of technical expertise and an unwavering commitment to quality, we elevate grinding from a routine task to a meticulous craft. Each rotation of the grinding wheel is a step towards perfection, where micron-level perfection is achieved, and the surface finish attains a level of excellence that surpasses industry standards.

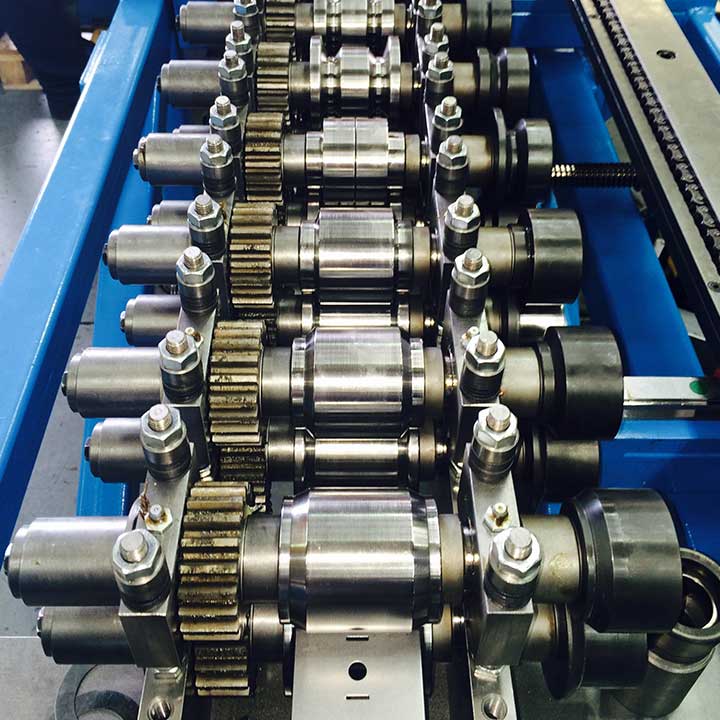

Roll Manufacturing

Roll manufacturing is a delicate balance of science and craftsmanship, and at VEPC, we have honed this balance to perfection. In the industrial landscape, the integrity of rolls is pivotal to uninterrupted operations and financial stability. The repercussions of damaged or broken rolls can be substantial, disrupting processes and affecting the bottom line. Recognizing this, it becomes imperative to safeguard against such setbacks by maintaining spare rolls within your facility. Velocity Engineering and Project Consultants offers a comprehensive solution to this challenge. Our expertise lies in the design, fabrication, and manufacturing of precision, critical, and process rolls tailored to client’s specifications, whether or not they possess manufacturing prints or OEM drawings.

Our meticulous process involves detailed measurements, CAD drawing creation, proposal of design enhancements, in-house manufacturing, and end-to-end management, assuring our customers of a reliable and efficient solution for your roll requirements. Our seasoned artisans, armed with state-of-the-art technology, meticulously craft rolls that meet the stringent demands of diverse applications, from paper and steel plastics and beyond, our rolls serve as indispensable components in myriad of industries.

Types Of Roll We Manufacture

We can manufacture a variety of rolls, ranging from simple, to the most complex one, such as:

- Calendar Rolls

- Press Rolls

- Breaker Stack Rolls

- Size Press Rolls

- Coater Rolls

- Wire Rolls

- Felt Rolls

- Breast Rolls

- Reel Spools

- Reel Drums

- Couch Rolls

Understanding Client Needs

Project Planning

Skilled Workfroce